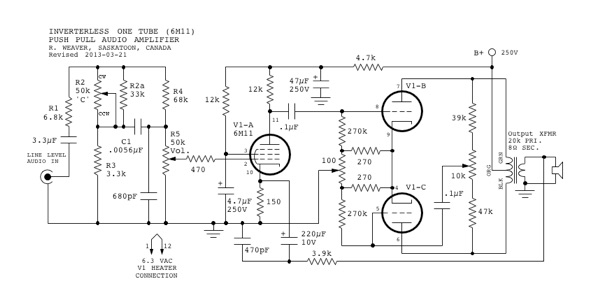

In the final circuit, I reduced the amount of negative feedback to compensate

for the insertion loss of the tone control. The original

feedback resistance value of 680 Ω was increased to 3.9 k.

The final schematic is shown below:

In addition to the tone control and negative feedback, a few other changes were made to the circuit.

A 470 ohm grid stopper resistor was added between the volume control and the pentode control grid. This corrects an instability problem that appeared during final construction. Further explanation of this is given below.

An adjustable bias circuit was added to balance the plate currents of the output triodes. I hesitated adding this, because it complicates the circuit and necessitates more set-up adjustments. However, since it only requires the addition of one trimmer pot and one fixed resistor, I decided to add it. The trimmer can simply be left at mid position, and the output stage will work the same as with the single fixed cathode resistor. But since there is no guarantee that the triode sections sharing the common envelope will be well matched, this gives the option of better matching to get the best possible performance from the amplifier.

The output transformer was changed from a 16k primary impedance to 20k primary impedance, as explained in the load line discussion.

Up to this point, I've made very little mention of what I used for the output transformer, other than to mention impedance. Output transformers are a critical component in tube audio amplifiers, and can make or break a design. So, it may be rather surprising to learn that I used common and very inexpensive 70 volt line audio matching transformers. Because of the way that the number of turns progress from tap to tap, it's possible to pick a centre tap and two other taps which give an equal number of turns on either side of centre. These transformers have the primary taps designated by wattage rather than impedance, and typically the wattage changes by a factor of two from one tap to the next. The wattage rating can easily be converted to impedance by dividing the square of the nominal line voltage rating by the tap wattage rating. For a 70 volt line transformer (actually 70.71 volts) having 4, 2, 1, 0.5 and 0.25 watt taps, this gives primary impedances of 1250, 2500, 5000, 10,000 and 20,000 ohms respectively. Starting from the primary common lead, the number of turns increases by √2 every tap. Hence, the number of turns doubles every two taps. So, having chosen a particular primary impedance, the tap corresponding to that impedance becomes one of the plate leads. The tap which is two down from the plate lead will be the centre tap, and the common lead becomes the other plate lead. For my amplifier I used a McBride model MCT70 4 watt transformer selecting the appropriate taps to give a 20,000 ohm primary.

Since these transformers were never intended to be used as push-pull output transformers, there is no reason to expect that the manufacturer made any attempt to balance the different sections of the primary winding. In fact, in doing some resistance measurements, it appears that there is a change of wire size between taps, resulting in a significant difference in DC resistance readings between the chosen centre tap, and the plate leads. The difference is much greater than what could be accounted for by the normal progressively increasing winding diameter. Hence the higher wattage sections must have larger gauge wire than the lower wattage sections. In any event the transformer primary DC resistance is negligible compared to the tube plate resistance, and the AC load impedance. Consequently, I don't expect the resistance unbalance to be a significant problem.

Of more concern is an imbalance in leakage inductance between the two halves of the primary winding. Indeed, I found that the transformer performed better when the primary common lead was connected to the plate of V1-C. In any event, considering the low price, the performance is surprisingly good. Though, given the overall 4 watt power rating of these transformers and the fact that the amplifier is putting out a fraction of a watt, they don't have to work very hard, and there is little chance of operating anywhere close to core saturation.

On the topic of core saturation, that is naturally not a problem in a push-pull amplifier, because the core flux produced by the DC components of the plate currents are opposite and cancel each other out.

I should point out that just because these transformers are inexpensive, it doesn't mean that they are not well designed. In their originally intended audio distribution application, they need to be reasonably well behaved and present a reasonably flat frequency response to the amplifier over the normal audio range. That is not to say that they should be classified as hifi, but given the conservative power level of this amplifier, the transformer has enough iron in it to give decent low frequency response, and high frequency response is generally not a problem in small transformers.

One final comment about using a transformer for something other than its intended purpose: These transformers are nominally rated 70.7 volts RMS. From the limited technical data that is available, there is no information indicating how much over voltage, if any, they can safely withstand. 70 volts RMS equates to 100 volts peak or 200 volts peak to peak on the primary. I am using this transformer with a plate supply up to 250 volts and the voltage swing across the primary winding could also be 250 volts peak to peak in some situations.

Because the transformer is operating well below its maximum power rating, there is little concern that it would fail due to current overload. The most likely failure mode would be a short circuit due to insulation breakdown caused by the higher than normal operating voltage. The worst case situation would be a short from primary to secondary. However, because of the very low impedance of the secondary winding, and because one side of the secondary is grounded, this would would quickly pull down the plate supply voltage, and the plate supply fuse should immediately open. This is my primary concern in properly sizing the plate supply fuse. Regardless, I would never under any circumstance use this as a headphone amplifier due to the possibility of electric shock, no matter how remote. For that matter, I would be reluctant to use any home built tube amplifier as a headphone amplifier.

Accordingly, I hereby warn anyone who may consider using one of these transformers in this or any other tube audio amplifier circuit, that they do so at their own risk.

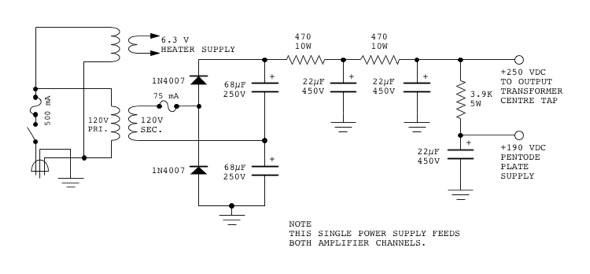

I eventually decided on a plate supply of about 250 volts, that with proper output stage biasing would have the triodes operating under their maximum dissipation rating of 2.25 watts except during conditions of maximum output, which will be infrequent. Getting a 250 volt supply during the prototyping stage was easily done. I simply used a transformer with a 350 volt secondary winding and then powered the primary side from a variac, so I could adjust it to any desired voltage. However, that is obviously not practical for the final design. Unfortunately, I had a very limited supply of transformers. I have an ample supply of 20 VA 120 volt isolation transformers. So I decided to use one of them in combination with a voltage doubler. The power supply circuit is shown below:

The two stages of filtering with the 470 ohm resistors and 22 µF capacitors are intended more for dropping the supply voltage to 250 volts, than for reducing ripple. Push-pull amplifiers are highly immune to power supply ripple.

In past projects I have added a filament winding to these isolation transformers in order to get all necessary voltages from a single transformer. However, for a stereo amplifier, the 1.5 amp total heater current would be pushing things. So, I opted for a separate filament transformer.

Note the fuses on both primary and secondary side of the plate supply transformer. These are important for safety reasons, and should not be left out.

Total plate current for both channels should never exceed 50 mA. If it does, then there is something wrong, and the fuse should blow. It's important to note that if the +250V B+ line should ever short directly to ground, the current draw will not exceed 370 mA because of the supply dropping resistors. Therefore, a secondary fuse rated higher than this value will not provide any protection. A 75 or 100 mA fuse allows normal operation, but will blow if current consumption increases to an abnormal level.

and I had to settle for some Panasonic miniature printed circuit mount types.

Because of this, it made sense to incorporate the volume and tone

controls along with all of the tone control components onto a single

printed circuit board, making for a very compact and tidy input

assembly. Or, so I thought.

and I had to settle for some Panasonic miniature printed circuit mount types.

Because of this, it made sense to incorporate the volume and tone

controls along with all of the tone control components onto a single

printed circuit board, making for a very compact and tidy input

assembly. Or, so I thought.

I should have had the good sense to stop with the tone control components, but since I was going to the trouble of making a circuit board I thought it would save a lot of trouble by adding some additional amplifier components onto the board as well. By the time I was finished, the circuit board included all of the amplifier components except for the tubes and the power supply. This wouldn't necessarily be a bad thing, except that the circuit board had to mount behind the front panel, with long leads extending to the tube sockets. In some cases the leads were up to 4 inches long, which I consider to be a rather bad practice in a high gain amplifier. Nevertheless, I had committed myself.

The volume and tone pots were mounted on the foil side of the board due to clearance restrictions. If they had been mounted on the component side, there would have been interference between the larger components and the front panel.

The black and white trim pots at the top edge of the circuit board are the output stage grid drive pots. The small blue multi-turn trim pots lower down on the board and closer to the sides, are the bias balance pots. It may seem strange to use such small trim pots that will be handling the output stage cathode current. However, the actual power dissipation is very low and well within the specs of these trim pots. Don't do this with a high power amp though!

The lower half of the circuit board is the tone control section, and is well isolated from the rest of the amplifier circuitry.

The capacitors that determine the tone control crossover frequency are the dark red ones mounted vertically at the lower part of the circuit board, just left of centre. They are plugged into a set of header sockets, so that they can be easily changed out, if I decide that I want a different crossover frequency.

The following series of photos shows various stages of construction.

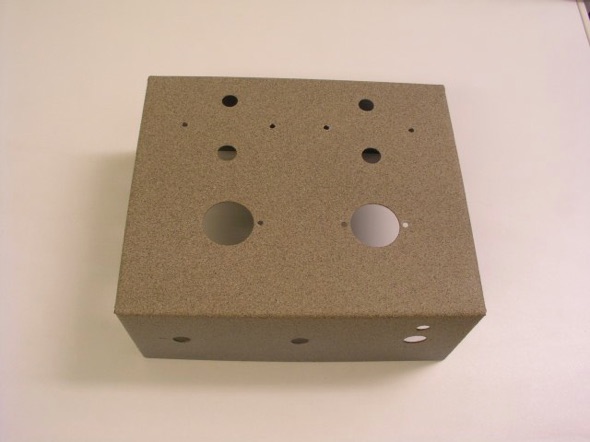

The main chassis which I fabricated from 22 gauge steel on a small sheet metal brake/shear. Here it's shown after drilling all of the mounting holes, and applying grey primer:

Top view of the chassis after applying a matte finish sandstone texture paint:

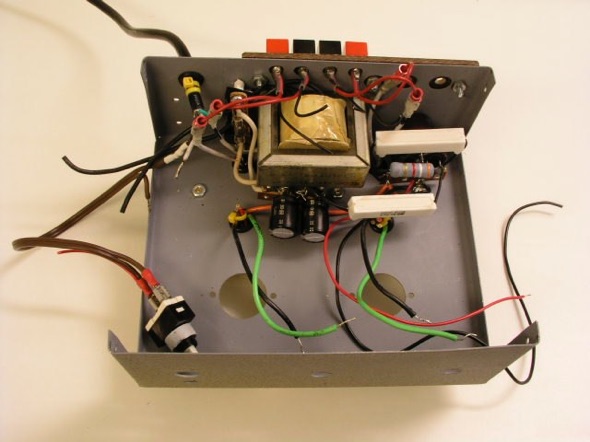

Two views of the chassis after mounting the plate supply components:

Two views of the chassis after the circuit board and tube sockets were installed. Also, the filament supply transformer has been installed:

Note the rat's nest of leads from the circuit board to the tube sockets. This is because I pre-wired the circuit board to the tube sockets before installing the sockets in the chassis, and I wanted to make sure that there was sufficient lead length. The intention was to test out the circuit, and once I was satisfied that there were no wiring errors, I could unsolder the leads, trim them to proper length, and then reconnect them.

It turns out that my concern about mounting all components on the circuit board was well founded. When I powered up the amplifier, the pentode stage had a tendency to break into oscillation (~70MHz). It was hardly surprising considering the high gain and the long leads. Luckily, the fix was quite painless. I added a 470 ohm grid stopper resistor at the pentode control grid, located right on the tube socket, and the parasitic oscillation immediately disappeared.

Note the circular black item mounted between the tube sockets. This is a 9-pin tube socket to be used as a test point during set-up. It gives easy access to the output stage common cathode point and the triode plates for both channels. This makes for simple grid drive and bias balance adjustments.

Shielded leads were used from the audio input jacks at the rear of the chassis to the circuit board, and again from the circuit board to pentode control grids. All other leads are unshielded. Because of the close proximity between the amplifier and the power transformers, I had some concern about induced hum, and had made allowance to install an aluminum shield between the power supply section and the amplifier section. It proved to be unnecessary, as there is no audible hum with this amplifier. (Well, to be entirely accurate, hum is very faintly audible when I place my ear directly against the speaker. It does not increase when the volume control is turned up, and it is 60 Hz hum, not 120 Hz supply ripple. I believe it's probably induced from the filament transformer. It could probably be shielded out, but I'll leave that for a future experiment.)

Remaining cabinet components including the bottom cover, wood side panels, front panel and two art deco corner feet:

The front and side panels, as well as the feet, are made from MDF (medium density fibreboard), finished with brown or black wood toner, then lacquer, and then dulled slightly with fine steel wool to give a satin finish (and hide the imperfections).

The completely assembled case:

Left to right, the controls are: Volume, Tone, Power Switch (with pilot lamp).

There are several methods for adjusting the output stage plate current balance. Regardless of the method, these adjustments are performed with no audio input signal present.

In theory, the simplest method is to use two ammeters to simultaneously measure the actual plate current of each triode, and then adjust the balance pot so that both ammeters read the same current. This is not particularly practical however, because two meters are often not readily available, and breaking the plate circuits to insert the meters is inconvenient.

Another method is to connect a single voltmeter from one triode plate to the other triode plate, and then adjust the balance pot until the meter reads zero voltage. This is much simpler, but it only works when the DC resistance of the two halves of the output transformer primary are identical. The chances of this happening are directly proportional to how much you paid for the transformer. These transformers cost me only seven dollars apiece, and not surprisingly, there is a significant difference between the resistance readings between the two halves.

The plate to plate voltage balance method can still be used, however. To do this, it's necessary to measure the DC resistance of the each half of the transformer primary, and then add a compensating resistance in series with the lower resistance winding (still somewhat inconvenient but easier than the two meter method). This resistance value is equal to the difference between the two resistance measurements. Once inserted, both windings will now have the same DC resistance value, and the balance can be quickly set. To make this easier, the 9-pin test socket has a jumper installed between the lower resistance transformer winding and the corresponding plate. So, it's simply a matter of pulling out the jumper, inserting an appropriate resistor, and then making the adjustment. Once the balance adjustment is complete, the resistor is removed and the jumper reinstalled. The slight change of plate load resistance that occurs when replacing the resistor with the jumper will have no significant effect on plate current balance, since the transformer DC resistance is much lower than the triode plate resistance which is the determining factor.

It should be mentioned that the amplifier should be given plenty of time to warm up before performing the bias balance adjustment. Though the amplifier will start operating within a few seconds after power is applied, I noticed that the plate current will take several minutes (or tens of minutes) to stabilize.

The remaining adjustment is the grid drive pot. For this adjustment, a single frequency sine-wave tone is applied to the amplifier input. Frequency is not critical. I used a 1 kHz signal. The signal generator level and/or volume control are adjusted so that the amplifier is producing a reasonably loud signal without overloading. An oscilloscope probe is connected to the triode common cathodes, and then the drive pot is adjusted to minimize the signal on the cathodes. A small second harmonic component will be visible on the scope trace, which cannot be eliminated, but it should be easy to null the fundamental frequency. If not, the level of input signal is too high and the amplifier is clipping. In this case the input signal level should be decreased, and the adjustment repeated. If an oscilloscope is not available, a sensitive AC voltmeter can be used, as long as it works at audio frequencies. With the AC voltmeter, the grid drive pot is adjusted for minimum reading on the voltmeter.

As mentioned above, frequency response is 20 Hz to 70 kHz. (This is with the 680 pF shunt capacitor disconnected. Naturally, the upper end of the response drops to a more practical frequency of about 20 kHz when the capacitor is installed.)

As I developed the amplifier, I performed a number of rough distortion measurements and finally a more careful one that indicates the harmonic distortion is less than 0.25% when power output is ≤75% of maximum. The measurement method was as follows:

Connect 8 ohm resistive load to amplifier output.

Feed amplifier input signal into oscilloscope channel 1.

Feed amplifier output into oscilloscope channel 2.

Record output amplitude (channel 2).

Switch oscilloscope to differential mode, and adjust channel 1 gain until fundamental frequency is nulled out on the scope trace. Whatever remains is distortion.

Measure amplitude of the remaining distortion signal, and divide by amplitude of original output level. Square the value to convert voltage ratio to power ratio. Multiply by 100 to get percent.

Though these are hardly laboratory grade measurements, the method gives a reasonable estimate of distortion.

Note that some distortion measurement methods simply calculate the ratio of voltages rather than the ratio of powers. These methods would give higher distortion numbers than the method used here.

It's interesting to note that the principal distortion component is the second harmonic which is normally not the case for a push-pull amplifier. However, it is completely understandable in this case. A traditional push-pull output stage has each output tube driven by identical signals (but 180° out of phase). Any even harmonic distortion will be in phase and will cancel out in the output transformer. In this circuit, the drive signals are not identical. The second triode receives its grid drive signal from the first triode plate that will introduce some even harmonic distortion. The second triode inverts and amplifies this distortion, which is now out of phase, and will not cancel in the transformer. The portion of the input signal that the second triode receives via the common cathode connection should not contribute even harmonic distortion. So, while the overall even harmonic distortion is higher than a conventional push-pull amplifier, it should still be less than that of a conventional single ended amplifier.

Even harmonics are generally considered to be less offensive to the ear than odd harmonics. In any event, I don't find it offensive. For that matter, I really can't detect the distortion in a listening test. What is normally far more offensive is intermodulation distortion, and this amplifier appears to be reasonably immune. Perhaps this is not surprising considering the excellent linearity of the output stage over a very wide range as shown on composite curves.

I was originally hoping I might be able to squeeze a bit more power out of this amplifier than what I ended up with, but after using it now for several weeks, I find that I rarely have the volume control turned up higher than about 25%. My speakers are a pair of vintage Realistic Minimus 7's which give excellent audio quality, in a small space. These speakers are much less efficient than what were typically used with tube amplifiers back in the golden age of tube audio. So, considering that the amplifier can easily drive them with more than adequate volume, I'm quite happy.