A Simple Nixie Display Driver

November 2019 Update - Note that there is now an Arduino

version of this project.

Most Nixie tube drivers require the obsolete and hard to find 7441 or

74141 TTL decoder driver ICs, or else high voltage driver

transistors. I wanted to produce a Nixie display using easily

obtainable parts (well… except for the Nixies), and at the same

time keep the parts count low. Given the state of the art in power

electronics, it seemed that there should be some modern high voltage

driver ICs available. In fact there are several. However, they are

not always easy to find in the small quantities that experimenters

require.

I settled on an A6818 vacuum

fluorescent display driver from Allegro Microsystems Inc. This chip

was relatively inexpensive, and available in small quantities from

suppliers such as Digi-Key.

Unfortunately, a few months after I built this circuit, the A6818

became obsolete, and inventories of the part disappeared almost

instantly, making this design obsolete as well. Fortunately, a reader

of this page advised me that there is a replacement. It is the Maxim

MAX6922 which has identical specs and identical pinout, and is

reasonably priced like the original A6818. I’ve now tested the

MAX6922, and it is identical in operation, so either one can be used

with no circuit changes. I’ve now revised the writeup, referring to

the driver IC as a MAX6922, but if you manage to locate some of the

older A6818s, they are interchangeable.

The

MAX6922 is a serial in, parallel out, 32 bit source driver, capable

of handling 60 volts, which is sufficient to drive Nixies. Nixies

actually require a sink driver, not a source driver, but the MAX6922

outputs can sink enough current to drive smaller Nixies such as the

Russian IN-16s that I used in my project. With 32 bits, one chip can drive a 3½ digit display.

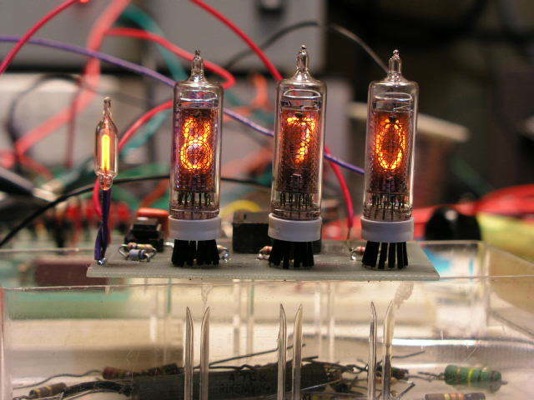

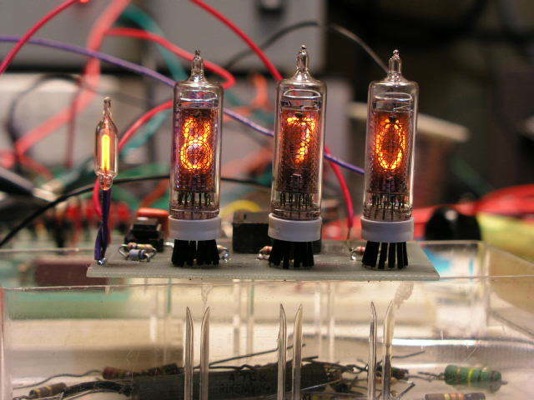

The chip comes in a 44 pin PLCC package, which fortunately can be socket

mounted in a through-hole PCB socket. As this picture shows, the

entire driver consists of only two ICs and a few passive parts. The

larger chip is the MAX6922, and the smaller one is a PIC 12F629 8-pin

microcontroller. Because the driver IC is serial input, it requires

only three control/data lines from the controller. That leaves two

I/O pins on the controller available for other functions. As well,

with careful planning, the data line going to the driver IC can serve

multiple functions.

The chip comes in a 44 pin PLCC package, which fortunately can be socket

mounted in a through-hole PCB socket. As this picture shows, the

entire driver consists of only two ICs and a few passive parts. The

larger chip is the MAX6922, and the smaller one is a PIC 12F629 8-pin

microcontroller. Because the driver IC is serial input, it requires

only three control/data lines from the controller. That leaves two

I/O pins on the controller available for other functions. As well,

with careful planning, the data line going to the driver IC can serve

multiple functions.

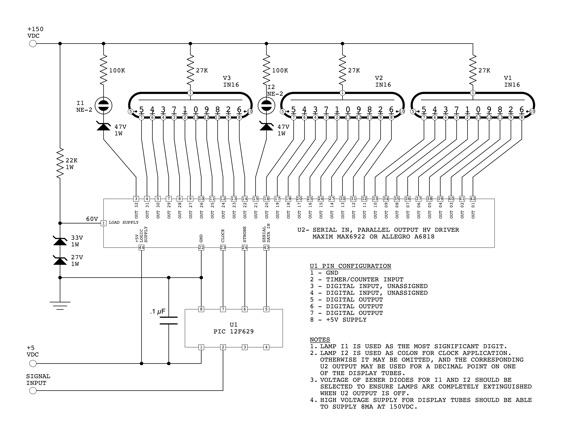

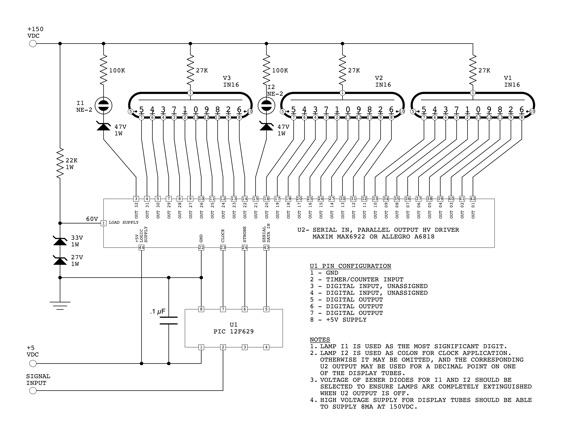

Here is the schematic of the display driver board:

Click for a larger View

One point that deserves some explanation is the requirement to supply 60

volts to pin 1 of the driver IC. This is the voltage supply input

used by the source output drive circuitry, required when driving a

device such as a VFD (vacuum fluorescent display). For a NIXIE

display we only require the sink driver part of the output circuitry.

Therefore, it would appear to be unnecessary to provide a load supply

voltage. However, during testing, it was found that the driver would

not work correctly without having a voltage at pin 1, equal to the

output ‘off’ voltage (approx. 60V). The 22k resistor and series

zener diodes provide this voltage. Note, that an earlier version of

the schematic showed a 60V zener. These are not normally available,

but a 33 volt zener and 27 volt zener, in series, is equivalent. The

current schematic shows this arrangement.

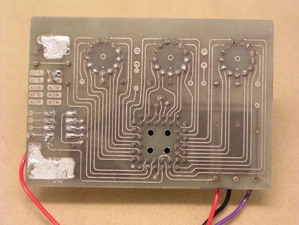

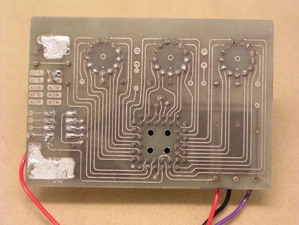

Here is a view of the bottom of the board showing the foil pattern. To

produce the board, I used the toner transfer method (which you can

google; there are several sites which will give a much better

explanation of technique than I will be able to do here).

This method

provides excellent results and was the only practical way to create

the required fine traces with minimum fuss and expense. After etching

the board, I used tin plating solution to tin the traces.

Unfortunately, the solution was getting old, and the result didn’t

look very good, and also made it somewhat difficult later to re-tin

the traces when I was soldering on the components. No matter; this

was a prototype, after all.

This method

provides excellent results and was the only practical way to create

the required fine traces with minimum fuss and expense. After etching

the board, I used tin plating solution to tin the traces.

Unfortunately, the solution was getting old, and the result didn’t

look very good, and also made it somewhat difficult later to re-tin

the traces when I was soldering on the components. No matter; this

was a prototype, after all.

I used this first prototype to

make a digital tuning dial for my homebrew radios. However, it could

just as easily be used as a digital clock, thermometer, voltmeter or

other device, depending on how the PIC is programmed, and with a few

additional components. A second MAX6922 could easily be cascaded on

as well, to provide a six digit display.

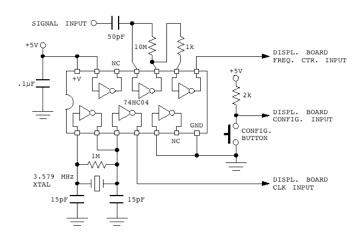

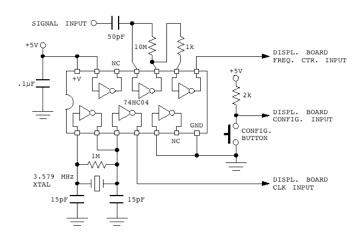

The digital tuning dial required the addition of a small piggy back

circuit board with the circuit shown here, for some additional

components.

For the tuning indicator, the internal clock was not

accurate enough, and so one pin had to be sacrificed for an input

from an external crystal oscillator on the piggyback board. Another

pin was used for a pushbutton input to allow user configuration. The

data output pin to the display driver was shared with the input

frequency signal, and the remaining spare pin was connected to this

same data pin. This connection is explained below. The piggyback

board contains a signal preamp/conditioner in addition to the crystal

clock. I used a 3.579 MHz television colour burst crystal for the

external clock, as they are inexpensive and I had several on hand.

The actual frequency is unimportant since the unit is calibrated in

the program to suit the clock frequency. The full schematic showing

the controller, display driver and extra components for the complete

frequency display is here.

For the tuning indicator, the internal clock was not

accurate enough, and so one pin had to be sacrificed for an input

from an external crystal oscillator on the piggyback board. Another

pin was used for a pushbutton input to allow user configuration. The

data output pin to the display driver was shared with the input

frequency signal, and the remaining spare pin was connected to this

same data pin. This connection is explained below. The piggyback

board contains a signal preamp/conditioner in addition to the crystal

clock. I used a 3.579 MHz television colour burst crystal for the

external clock, as they are inexpensive and I had several on hand.

The actual frequency is unimportant since the unit is calibrated in

the program to suit the clock frequency. The full schematic showing

the controller, display driver and extra components for the complete

frequency display is here.

To measure the input frequency,

the controller sets up “Count Mode.” In this mode, pin 5 is

configured as a high speed counter, and pin 3 is configured as an

input to prevent it from affecting the signals on pin 5. The counter

is enabled for 10 ms, and the cycles of the input signal are counted.

At the end of this period, pin 3 is reconfigured as an output, and

its low impedance forces the counter input low, disabling the

counter. Only the high order 8 bits of the counter can be directly

read by the program. To read the low order 8 bits, a technique

described in Microchip’s Application Note AN592 is used. Pin 3 is

toggled until the prescaler overflows into the high byte. This is

detected in the program, and the number of times pin 3 was toggled is

equal to the original value of the prescaler. Once both the high and

low byte of the counter are recovered, the IF offset is subtracted

from the count to get the actual receiver frequency. The resulting

number is converted from binary to BCD which in turn is used as an

entry in to a lookup table to determine the correct lines to power on

the Nixie tubes. Pin 5 is now configured as an output for serial data

to the display driver (with pin 3 configured as an input again), and

the line select data is shifted out to the display driver.

The pushbutton connected to pin

4 is used to select which IF offset to use. Most of the common IF

values are stored in a table, and pressing the configuration button

cycles through these to select the desired one.

Final Assembly

I wanted to construct a case

with a retro style to suit the Nixies. For my other radio projects,

I've used MDF (medium density fibreboard) with a dark walnut stain

which somewhat resembles a Bakelite finish.

I used the same technique here, with a 5 inch square piece of MDF with

the edges routered, and the bottom hollowed out to accommodate the

circuit board. The Nixie tubes are protected with glass test tubes

which were cut down and tinted amber. The red pushbutton in front is

used to select the IF offset. A small vent hole over the driver IC is

covered by a small circular piece of perforated metal taken from an

old computer speaker.

The above photo shows the underside of the housing after it had been

hollowed out using a router. This was done using an extremely simple

box shaped jig built on a piece of scrap plywood. The jig simply

forces the router to stay within a rectangular area within the

workpiece. Some final adjustments were done using Forstner bits in a

small drill press, and a bit of hand chiseling.

In this photo, the components are shown laid out on the baseplate which

is black painted 1/8” hardboard. Note that the power supply is

external. Although there is room next to the preamp/clock board for a

small switchmode power supply, this would have generated far too much

radio frequency interference to be useable with a radio. Instead, an

analog power supply with a normal transformer was constructed and

mounted in-line in the power cord, much like a laptop computer power

supply.

Finally this last photo, below,

shows the unit in operation with my one-tube superhet receiver.

Miscellaneous Bits:

The source code listing for this project is here.

Please heed the warnings in the comments.

I had intended to post circuit board patterns. However, when the

A6818 driver IC went out of production in 2010, a board pattern based

on the A6818 seemed pointless. Now that a drop-in replacement has

been found in the MAX6922, I plan to dig up the PCB files and post

them. I’ve also been looking at upgrades to the original circuit to

handle a full 5 or 6 digits, and hope to have printed circuit layouts

for those available once they are complete.

Back to:

Projects

Home

This page last updated: April 4, 2023

Copyright 2009, 2023, Robert Weaver

The chip comes in a 44 pin PLCC package, which fortunately can be socket

mounted in a through-hole PCB socket. As this picture shows, the

entire driver consists of only two ICs and a few passive parts. The

larger chip is the MAX6922, and the smaller one is a PIC 12F629 8-pin

microcontroller. Because the driver IC is serial input, it requires

only three control/data lines from the controller. That leaves two

I/O pins on the controller available for other functions. As well,

with careful planning, the data line going to the driver IC can serve

multiple functions.

The chip comes in a 44 pin PLCC package, which fortunately can be socket

mounted in a through-hole PCB socket. As this picture shows, the

entire driver consists of only two ICs and a few passive parts. The

larger chip is the MAX6922, and the smaller one is a PIC 12F629 8-pin

microcontroller. Because the driver IC is serial input, it requires

only three control/data lines from the controller. That leaves two

I/O pins on the controller available for other functions. As well,

with careful planning, the data line going to the driver IC can serve

multiple functions.

This method

provides excellent results and was the only practical way to create

the required fine traces with minimum fuss and expense. After etching

the board, I used tin plating solution to tin the traces.

Unfortunately, the solution was getting old, and the result didn’t

look very good, and also made it somewhat difficult later to re-tin

the traces when I was soldering on the components. No matter; this

was a prototype, after all.

This method

provides excellent results and was the only practical way to create

the required fine traces with minimum fuss and expense. After etching

the board, I used tin plating solution to tin the traces.

Unfortunately, the solution was getting old, and the result didn’t

look very good, and also made it somewhat difficult later to re-tin

the traces when I was soldering on the components. No matter; this

was a prototype, after all.

For the tuning indicator, the internal clock was not

accurate enough, and so one pin had to be sacrificed for an input

from an external crystal oscillator on the piggyback board. Another

pin was used for a pushbutton input to allow user configuration. The

data output pin to the display driver was shared with the input

frequency signal, and the remaining spare pin was connected to this

same data pin. This connection is explained below. The piggyback

board contains a signal preamp/conditioner in addition to the crystal

clock. I used a 3.579 MHz television colour burst crystal for the

external clock, as they are inexpensive and I had several on hand.

The actual frequency is unimportant since the unit is calibrated in

the program to suit the clock frequency. The full schematic showing

the controller, display driver and extra components for the complete

frequency display is

For the tuning indicator, the internal clock was not

accurate enough, and so one pin had to be sacrificed for an input

from an external crystal oscillator on the piggyback board. Another

pin was used for a pushbutton input to allow user configuration. The

data output pin to the display driver was shared with the input

frequency signal, and the remaining spare pin was connected to this

same data pin. This connection is explained below. The piggyback

board contains a signal preamp/conditioner in addition to the crystal

clock. I used a 3.579 MHz television colour burst crystal for the

external clock, as they are inexpensive and I had several on hand.

The actual frequency is unimportant since the unit is calibrated in

the program to suit the clock frequency. The full schematic showing

the controller, display driver and extra components for the complete

frequency display is